Designing for Train Automation: High-Fidelity Prototypes for a Smarter Fuel-Saving Journey

Role: UI/UX Designer, iOS Developer, and Motion Specialist

Duration: Aug 2018 – Jan 2019

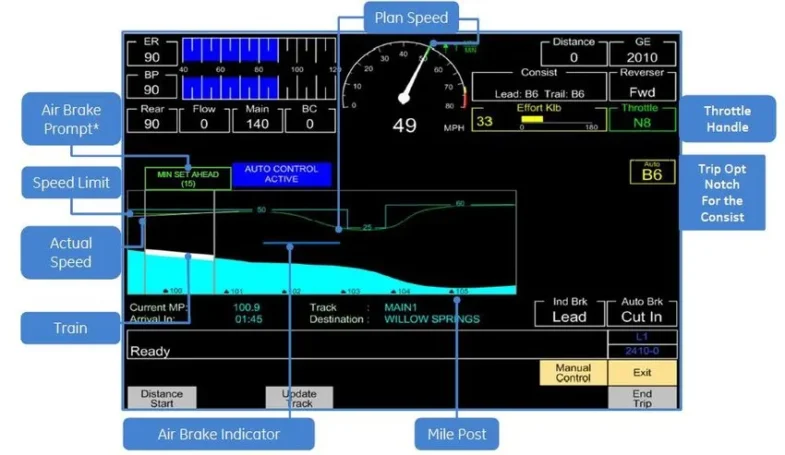

The Product: GE Transportation wanted a system that calculated the optimum speed profile and then automatically controlled locomotive throttle and dynamic brakes to reduce fuel consumption and provide efficient train handling.

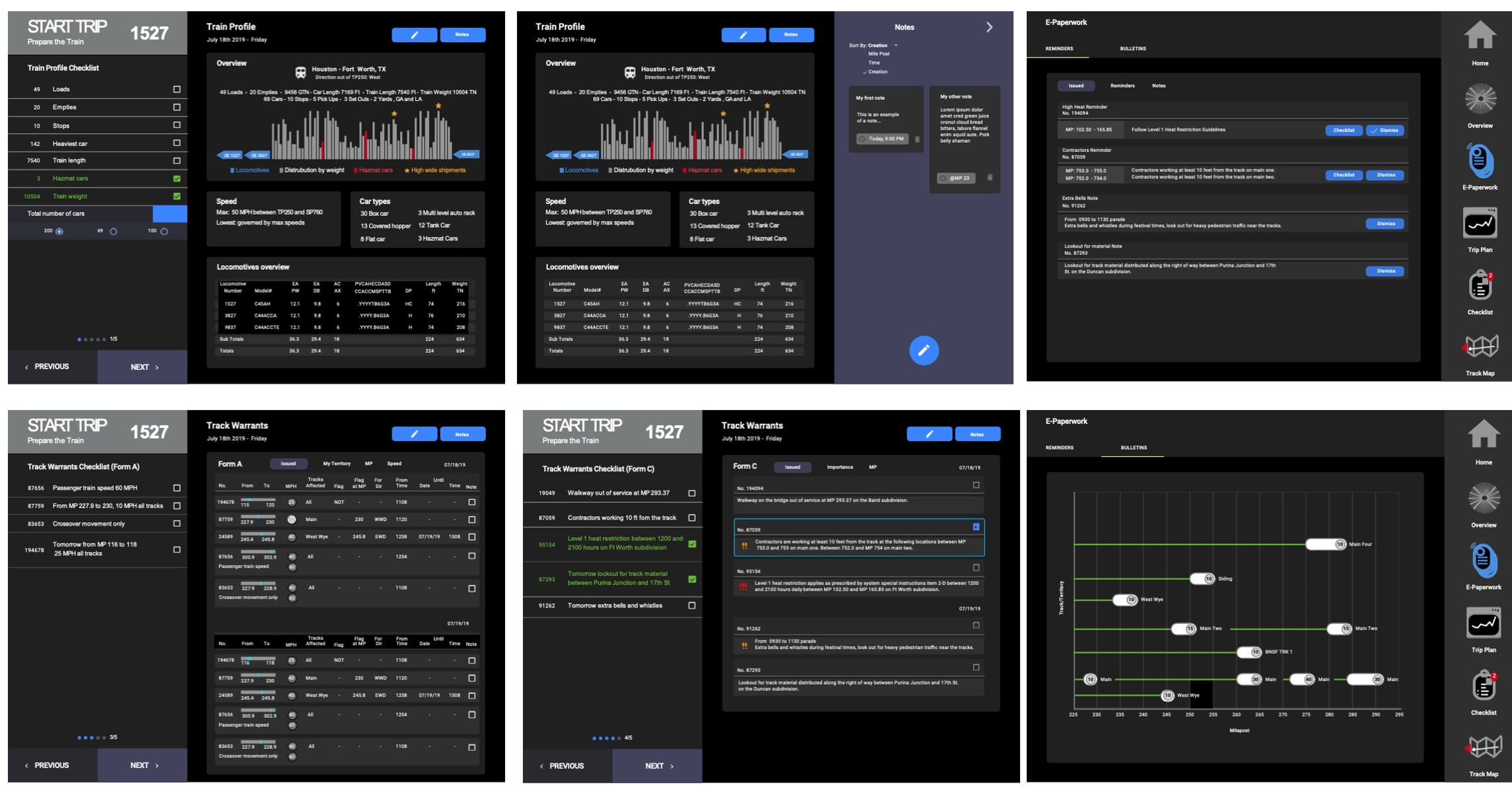

Responsibilities: Developed high-fidelity mockups and prototypes for an iPad app, designed motion interactions, exported UI assets for development, and collaborated with researchers and developers to refine the experience developed in a Unity application.

Due to privacy restrictions, I can’t share detailed visuals from this project. However, here are some key insights into my contributions, highlighting publicly available information.

As GE Transportation’s product portfolio expanded, the need for a smarter, more fuel-efficient solution for train operations became critical. The challenge was to create a system that could automatically optimize train speed and manage throttle and braking without compromising safety or productivity.

Problem

Conductors relied on dense manuals and manual controls to navigate complex routes, leading to inconsistent fuel use and operational inefficiencies. A smarter, more intuitive system was needed to support automation and improve trip handling.

Solution

I designed high-fidelity prototypes and motion-rich interfaces for a tablet-based app that streamlined train operations. The UI simplified complex route data into intuitive controls, helping conductors follow an optimized speed profile. I collaborated closely with researchers and engineers to ensure the experience aligned with operational needs and technical constraints.

Impact

The Trip Optimizer prototype not only improved fuel efficiency by automating train acceleration and braking but also reduced the reliance on manual operations, improving the overall safety and productivity of train handling. The solution laid the groundwork for future iterations that would enhance the scalability and automation of train operations globally.

Autonomous Trains

What does it take to enable train automation, improve train handling, and save fuel?

An on-board and GPS systems, railroad aspects and train characteristics — such as length, weight, speed limits, travel time, locomotive performance, ramps and rugged terrain — to determine travel standards, and more.

Understanding the user

Imagine a railroad with so many obstacles that, in order to preserve the locomotives, the train operators needed to drive according to different parameters, taking into account unstable and remote areas, sharp curves and speed and acceleration variations.

To give you an idea, train drivers had an instruction manual to drive the train in different sections of the track, with specifications for each car and locomotive, contemplating several territorial and operational factors!

The Product: Trip Optimizer

GE Transportation wanted a system that calculates the optimum speed profile and then automatically controls locomotive throttle and dynamic brakes to reduce fuel consumption and provide efficient train handling. In addition to standardize trips, offer greater operational flexibility, and avoid unplanned stops.

With Trip Optimizer, trains should run on time, operate more smoothly, and use fuel more efficiently – resulting in fuel savings and corresponding emissions reduction.

Project Breakdown

In 2018, I joined GE to work on Trip Optimizer, a digital “autopilot” system for train operations designed to reduce fuel consumption and improve train handling. It intelligently controls acceleration and braking by factoring in GPS data, train length, weight, terrain, and other operational parameters—ultimately enhancing safety, efficiency, and sustainability.

I collaborated with a small cross-functional team—including a UX researcher, product manager, and three software engineers—across GE Transportation teams in the U.S. and Brazil. Our goal was to design a functional prototype with interactive controls for user research and a tablet-based mobile app that served as a checklist tool for conductors.

I led the design process end-to-end, from defining user flows and wireframes to crafting high-fidelity UI, motion design, and interactive prototypes. My work was grounded in close collaboration with researchers and developers to align user needs with technical constraints and business goals.

After an initial brainstorming and sketching phase, I developed a clear understanding of how the solution needed to function, identifying five key steps: Initialize Trip, Trip Data, Train Data, Restrictions, and Start Trip.

I used Sketch and Adobe XD for the iPad wireframes, mockups, and prototypes. Illustrator was my tool for designing GUI elements, while After Effects and Lottie handled animations.

The final product

Below are screenshots of the in-train system in action, used onboard trains.

Impact

Through this project, I gained valuable insights into designing for the transportation industry. One of the most rewarding aspects was witnessing the real-world impact of automation systems—reducing emissions, optimizing train handling, and driving cost savings.

Today, nearly 3,000 trains worldwide operate daily using this digital solution, collectively covering over 16 million kilometers with smart technology.

GE Transportation became a division of Wabtec following its acquisition from General Electric on February 25, 2019.

What I learned

Designing for high-stakes, real-world environments.

Working on Trip Optimizer taught me how to design with precision, balancing user clarity with system complexity. I learned the importance of aligning technical capabilities with real-time operational demands, especially in safety-critical industries.

What I would do differently

Invest time in onboarding—even when time is short.

I joined this project mid-stream and had to deliver quickly. While I met design goals, I now realize how a deeper understanding of the system architecture and operational context early on could have led to even stronger design decisions. In the future, I’d carve out time to onboard strategically, even in fast-paced environments.

Cross-functional insight

Designing for scale in critical systems

This project brought together UX, research, engineering, and rail operations to deliver a global-scale tool. By embedding design into the system from early prototyping to implementation, we helped shift the mindset around automation—showing how intuitive design could directly improve performance and sustainability in rail logistics.